SERVICES

Trymoss Engineering offers the following services to the following industries

MINING

Trymoss Engineering works within the mining industry providing equipment repair services. These services consist of:

Hydraulic cylinder repair

Hydraulic cylinder manufacture

Hydraulic cylinder design

Machining service for worn and new parts.

Precision machined components

We can design new components from samples provided or obsolete part drawings and we specialise in the manufacture of hard to find components.

OIL & GAS

Trymoss Engineering is a key player in supplying components and machining services to the oil and gas fields of Australia. We manufacture and design our products in-house and use API specified quality materials. Our experience and knowledge from working with major contractor’s and operators means we have a good understanding of the vast scope and specifications required to complete our client’s projects to high industry standard.

We supply the upstream market with components that include; spectacle blinds, spade blinds, ring spaces, orifice flanges, orifice plates, pipes nipples and much more.

We supply the downstream market with down-hole thread repairs, new thread cutting, bucking connections and tool servicing. One particular component we manufacture and service is our very own Centrefire System. For more on the Centrefire please head to www.HPHTDrillingTools.com

TRANSPORT

Trymoss Engineering offer the transport industry services such as:

Refurbish and recondition worn and used parts

Light fabrication repairs

Tail gate cylinder repairs

Slide and tilt tray cylinders

Machining

Our machining service has seen repairs from the simple pin and bush setup to the complex manufacture of axles and housings.

AGRICULTURE

Trymoss Engineering services the agriculture industry through repair and installation of products such as hydraulic components and manufactured products. We have extensive experience in the manufacture of parts and components within the food industry both pre-harvest and post-harvest. We have a good understanding of the industries demand for high quality products and fast lead times, especially during the harvest season. We have our own in house design and built range of conveyor lines that are custom built for our clients’ needs and space.

TRICELL

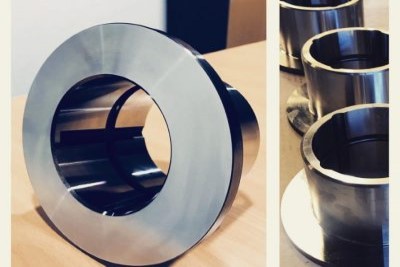

Trymoss Engineering has its own brand of hydraulic cylinders known as “Tricell”. The Tricell brand is a division of Trymoss Engineering which specialises in the manufacture of hydraulic cylinders. We manufacture high and low pressure hydraulic cylinders ranging from 500psi to 10,000 psi.

Tricell is now widely used throughout Australia. We have designed the Tricell cylinder to meet our high standards of performance and quality. Tricell excel at the manufacture of the Ag style cylinder, Press Cylinder and heavy duty cylinders.

HYDRAULIC CYLINDERS

Trymoss Engineering has designed and built hydraulic cylinders since the company was established. Our experience of hydraulic powered equipment expands over 30 years and we provide our clients with fast and affective service. We have the capability and knowledge of designing and manufacturing hydraulic cylinders. Our hydraulic cylinder service allows us repair cylinders to samples provided and or client specified drawings. We provide this service for all cylinders irrespective of the size and make.

Trymoss Engineering specializes in the refurbishment of hydraulic cylinders used on earthmoving equipment. Our competitive price and quick lead times has transformed Trymoss Engineering into a leading repairer of OEM cylinders.

PRECISION MACHINING

Trymoss Engineering provide a premium quality machining service to our clients. We provide machining services such as:

Turning

Boring

Milling

Drilling

Threading

Keyway cutting

Down-Hole Threading for the Oil and Gas fields

Our machining services are completed to extremely tight tolerances, high standards and has been exported all over the world. Our quality standards and knowledge has been employed for over 30 years in the machining industry. We pride ourselves on pushing the boundaries of quality and continue to evolve through implementing higher quality standards within our quality systems.

We enjoy working meticulously with our clients to ensure that the client is delivered a product that meets or exceeds their expectations. We provide machining services for all industries and all quantities.